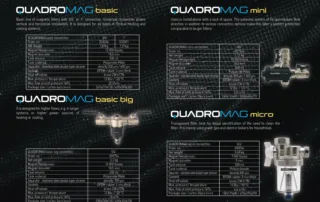

Quadromag Micro

Transparent filter tank for visual identification of the need for filter cleaning.

It is mainly used under gas and electric household boilers.

Technical specification:

| Container material: | polycarbonate |

| Shut-off valves: | brass CW 617N |

| Neodymium Magnet: | 7 000 Gauss |

| Magnet diameter: | 9mm |

| Separator: | Stainless steel double-layer strainer in a plastic frame |

| Strainer density: | 800μm |

| Strainer density to order: | 100μ / 600 μm |

| Seals: | Rubber EPDM 3mm |

| Max. temperature: | 90°C |

| Filter tank volume: | 250ml |

| Connecting to the system: | 3/4″ |

| Operating pressure: | 3 bar |

| Max. pressure: | 10 bar |

| Max. flow rate: | 4,6m3/h |

| Net weight: | 0,68kg |

| Box size/weight: | 130x175x80 / 0,70kg |

| Quantity per carton: | 20 pcs |

| Carton size/weight: | 475x375x290 / 14,0kg |

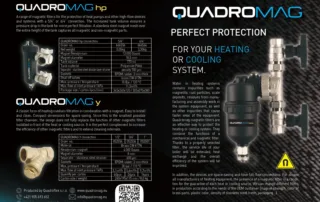

Why is it important to have quadromag included in the system?

Why should we include QUADROMAG – magnetic dirt separator – in our system?

Is it worth investing?

QUADROMAG magnetic separators are installed in all boiler installations to protect your new equipment as well as the entire system.

Many of us have this device installed on the advice of an installer, but few of us know why such a device is actually needed and what it actually does to the system.

Today, the manufacturer’s warranty for any boiler is conditional on proper use and protection of the appliance, which requires the QUADROMAG filter.

The first step is to install a mechanical dirt filter and a magnetic filter on the return line before the boiler, which is especially important in the case of condensing boilers installed on an existing radiator system, but also with underfloor heating. These two filters can be combined by purchasing the combined magnetic filter QUADROMAG, which combines the functions of a mechanical dirt filter and a magnetic dirt separator into one filter.

The most common causes of malfunctions

Heat exchanger leaks

This is the worst possible scenario, as replacing the heat exchanger can cost up to 300-600 EUR (depending on the type and brand of the boiler), at which point it is already worth considering buying a new one. This happens because impurities and iron oxides circulating in the system settle on the inner surface of the heat exchanger, which leads to higher heat absorption in this area.

This causes the filler to burn out, weakening the material and burning out the heat exchanger at this point. In other cases, it becomes clogged, which prevents the flow of liquid. In this case, the circulation pump and the heat exchanger gradually fail, often all at once.

Circulation pump fails

According to the new EU directive, the three-stage pumps in the units had to be replaced by pumps that could be modulated over the entire speed range. This brings a reduction in energy consumption of up to 70%.

Of course, the new types of pumps require a higher quality of the heat transfer medium. The technical solution is to install a permanent magnet shaft in the pump.

Without the QUADROMAG magnetic filter, magnetized impurities (rust, metal fragments) circulating in the system will stick to the shaft and in 1-2 years the pump will lose its performance and seize.

Materials used in Quadromag filters

Filter container material POLYAMIDE PA66

Nylon PA66 is a thermoplastic. It is made by a process called polycondensation of adipic acid and adipic diamine. It is widely used in the automotive industry, electronics, electrical appliances, machinery, chemical industry, aerospace and other industries.

- 1

It is a heat-resistant plastic, i.e. it has a high melting point, therefore it is used for technologies that require higher temperatures or a material with high thermal resistance (heat transfer on the walls of the container)

- 2

It has high elasticity, so if it falls on the ground, for example, it will not be damaged because it absorbs impact energy well, i.e. it is not a fragile material.

- 3

It has high resistance to chemical elements, most acids, alkalis and salts, and is also resistant to inhibitors and other chemical compounds used in cleaning heating or cooling circuits.

- 4

Long service life in material strength, which is very important with constant or cyclical pressure increases in systems, the material does not get tired, so to speak.

- 5It has high tensile and bending strength, so it is sometimes used, depending on the technology, as a substitute for metal to reduce the weight of the product.

- 6

It resists abrasion from dirt in systems, the material has a low coefficient of friction, which is very important for achieving a long filter life.

Gasket material EPDM, 3mm thick

Synthetic rubber EPDM (Ethylene Propylene Diene Monomer) has excellent properties such as resistance to weathering, oxidation and UV radiation, chemical resistance, electrical insulation and thermal conductivity, which makes it an ideal material for various applications, including seals. We chose a thickness of 3 mm so that the seals can be used multiple times, especially for cleaning and maintenance of the filter as well as your heating or cooling system.

Material brass CW617N

We chose the material brass CW617N for the production of valves and other metal parts of filters because of its excellent machinability, very easy processing. It is an alloy of copper, zinc and lead, which has wide application in the cooking and refrigeration industry. It has unrivaled resistance to corrosion, resistance to chemical elements, and can be easily and permanently surface-treated by nickel plating (silver color).

Neodymium magnets – the basic part of magnetic filters

Neodymium magnets are also known as supermagnets, or permanent magnets – and rightly so. Since they have amazing strength even in the smallest dimensions, they are among the strongest permanent magnets in the world. The magnetic material of our superstrong magnets is an alloy of neodymium, iron and boron (NdFeB). Our filters use different strengths of these magnets depending on the volume and use of the filter. Thanks to our experience, we use neodymium magnets of the appropriate size and strength. However, if the customer chooses a different filter design, whether its shape or volume, we will adapt the magnet to this filter so that the overall efficiency of the filter is the highest, the strongest magnet does not always make the filter the most efficient. In case you would like any magnet strength, we will be happy to fit the magnets according to your order.

Advantages of neodymium magnets in a nutshell:

- 1

Extremely strong adhesion

- 2

Suitable for limited space (miniaturization)

- 3

Even the smallest neodymium magnets are as strong as larger conventional ferrite magnets

Stainless steel filter mesh

Our magnetic filters perform the function of a double filter, a filter for mechanical impurities and a so-called magnetic filter, i.e. a separator for magnetic impurities such as megnetite, sludge, it captures corrosion, already precipitated scale and residues from assembly work. The stainless steel filter mesh is made of SUS316SS stainless steel, it can have different density of gaps depending on the type of filter, its use, or installation position, or according to the customer’s order. Different technologies require different density of the filter mesh from 50..-..800 μm (microns). In some devices, especially if the filter mesh density is 300 μm and less, for shape stability we add a lower density mesh for support and resistance to the flow pressure of the medium. IF filtration is to take place over a large area such as in the QUADROMAG HP filter, we automatically have to supplement the support mesh, because otherwise, the high pressure would deform the filter mesh, which would lead to higher pressure losses and fault messages from heat pumps or boilers.